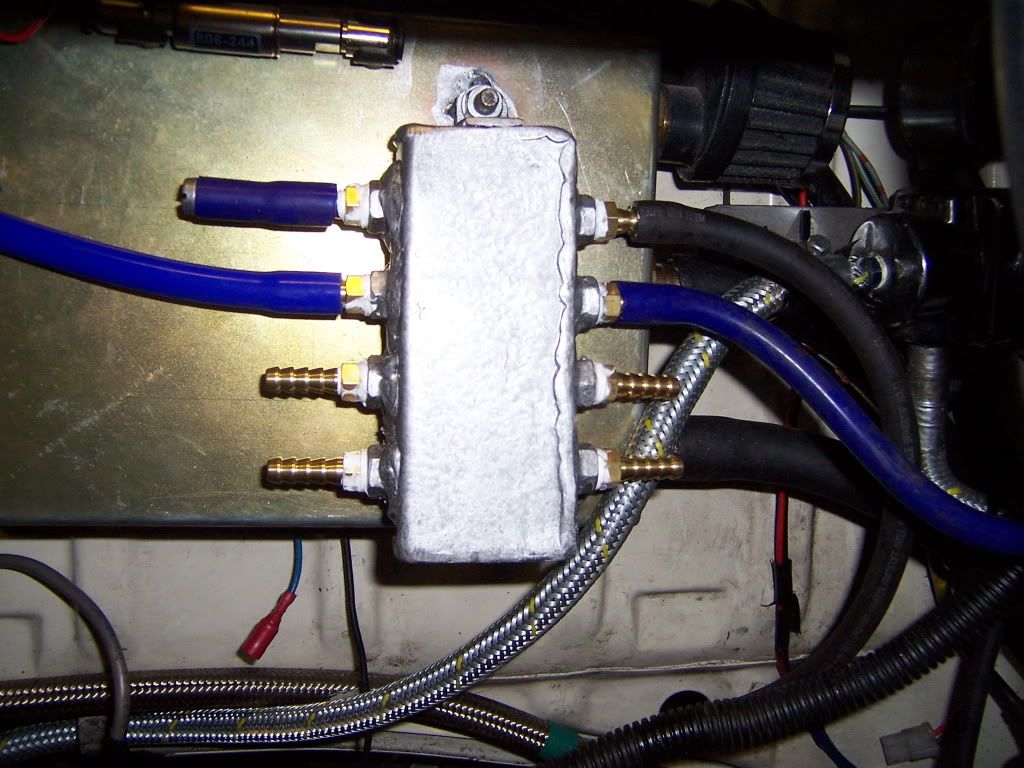

Made a vacuum/boost box for all the pressure lines to connect to instead of all the 'T'- connections in the lines I had up untll now.

I hope it gives a better boost signal this way, which is important for the MAP sensor, fuel pressure regulator and also for the BOV.

In the meantime, I have a 6-puck spring centered on the way from KEP (dual disk is a bit too much $$ for me at this moment) and the flywheel and pressure plate have been machined flat again. To get the diafragma fingers 'straight' (general consensus being that that is when the most torque can be transmitted), we had to machine the outer edge of the flywheel (where the pressure plate resides onto) some 1.5mm deeper than stock.

The ratio of machining depth to fingers moving is approx. 1,5 to 1.

So, 1.0 mm machining gave about 1.5mm finger movement with this pressure plate. Never thought it needed to be that much. I hope it works out as I have anticipated.

The 6-puck is equally thick as the organic one KEP said (8.0mm), so I hope it gets here on time so I can use it next saturday on our first local drag race meet of this year.