Well, I have a bit of an update on my new engine. The case should be cut for the larger cylinders, and full-flowed. My new crank was stolen off the pallet before arriving to it's destination...sigh, so I'll order another one. The heads though, I had planned on reusing from my old motor. NOPE! Darren text messaged me last week "All your valves and guides are toast. 1 cracked, and 1 broken keeper. 1 head cracked. Valve seats pounded out, retainers show heavy wear. Valve float." He then sent another text..."Don't you have a tach?!" Heh heh, well, I guess there will be new heads on the order-sheet as well. Not a bad idea, as I'm going to be upgrading to IDF44's so moving up on the valve size will be ideal for those. I think I'm going to finally get rid of the 914 tach, and look into a better ignition system with rev-controlling capabilities.

While I work out the various engine specs, I'm continuing on with other chassis projects. The factory e-brake has been cut out, as well as the unused heater control lever. I’ve removed the Accusump valve and lines (for now), the Z-Bend shift rod and the shifter setup I had. I’ve also started removing the POR15 from the tunnel. It’s amazing, use that stuff on “used” metal, and I can barely get it off with a grinder and an 80grit flap wheel. Use it on ‘new’ metal (like the floor boards) and it just peels up, as you can see. I’m hoping the surface rust will help it to finally stick!

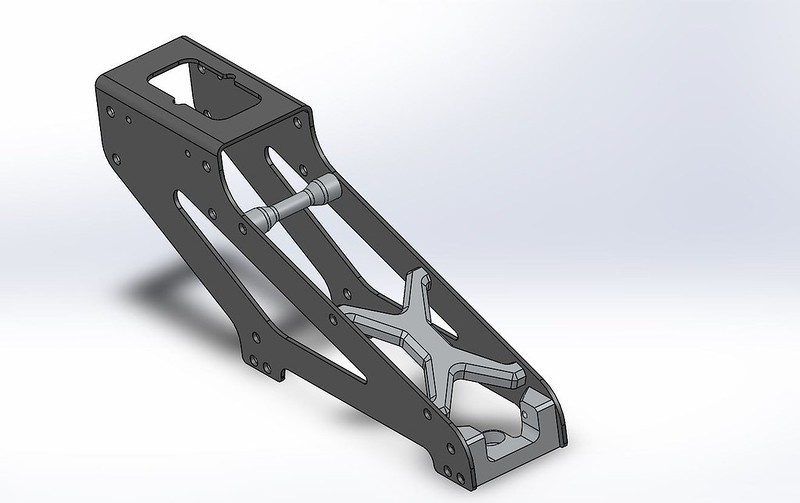

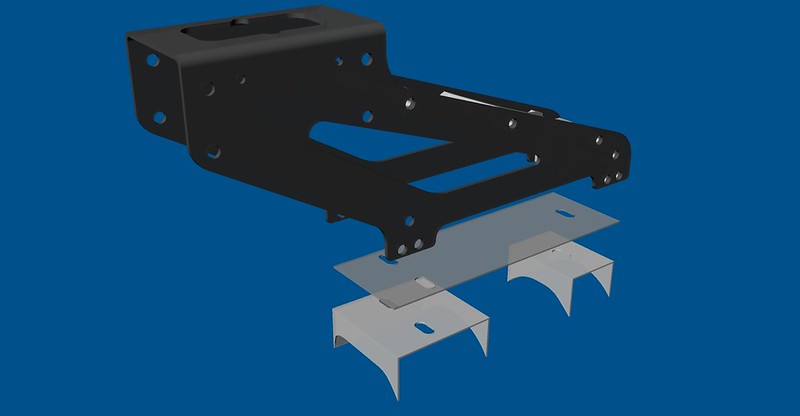

I have some personal modifications planned for the Hargett shifter, which won’t improve the performance level at all…but will improve my personal driving experience far more then anything else I’ve done. I managed to rope Stenhouse Racing into giving me a hand, as he has loads of design experience, and a CNC mill. He keeps teasing me with renderings of the shifter…but always leaving out my custom bits!

I did realize, however, that Colin’s work would allow me to draw up the pieces I need to make mounts for the shifter. I am going to get the pieces water jet cut, and then weld them to the tunnel. The driver’s side will be closed off, while the passenger side will be open so I can reach whatever hardware I use underneath.

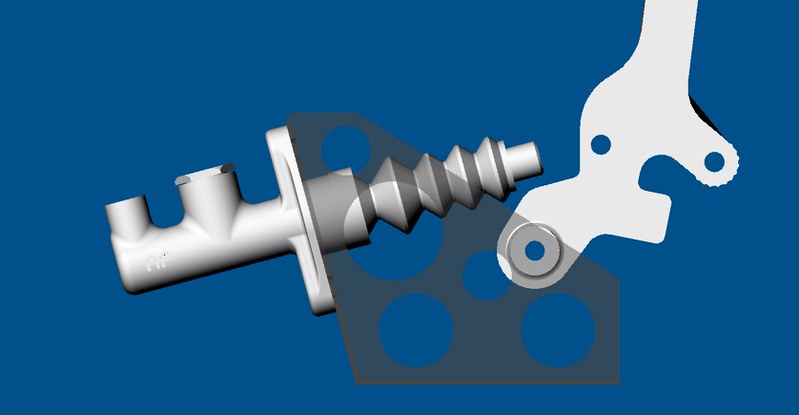

I’ve also started working on the handbrake. I spent a lot of time on Demon-Tweeks trying to find a handbrake I liked, which wouldn’t break the bank. Lots of measuring, scaling, and sitting in the car. Nothing fit the bill. I went to Rocket Rally, and found a horizontal e-brake on the wall which wasn’t being used. YOINK! The perfect example to R&D (review and duplicate) from! I have a bunch of finishing up to do on the handle, but I’ve got enough done that I can print out a drawing, cut it from cardboard and test the height & angle in the car. Problem is, I need my shifter back in order to figure out exactly where it will sit! I'll have an option for locking it on, and I've built in a tab which allow me to run a cable to the factory e-brake cables. I wasn't planning on using the cable e-brake setup, but may have to scale back my plans for the winter and keep the brakes that I have on the car for the time being. The cable setup will be more for 'visuals' and 'legal' vs. very functional.

-Dave