|

|

#1

|

|||

|

|||

|

Bugged Build Thread

Hello online Beetle community!!

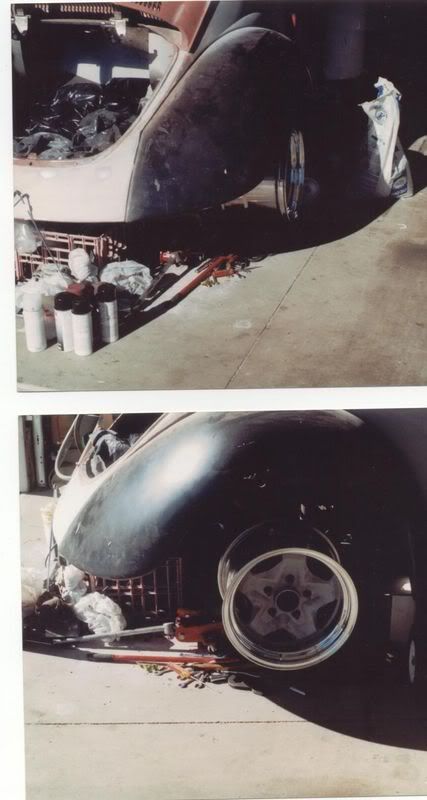

My name is Zach, I live in Tempe, AZ and I purchased my 1974 Super Beetle in July of 2009. This is my first car project undertaking and I wanted something affordable and simple enough for me to learn on. I hear many novice car enthusiasts asking whether or not they can undertake this or that, and hopefully my build will show them the reality of building a beetle, affordable techniques, and the complications they will likely face. I had a lot of ideas in the beginning and it is funny how they have transformed from dream to reality. At first reading every page you can find on a given topic seems comprehensive, but you quickly learn there is more to do then a "how-to" usually suggests. A big part of starting a build is realizing the cost. It is hard to see sometimes where the money will go, and it is easy to think you can get by with a certain budget; be prepared to spend more than you originally expect; if you want to do it right. You think you just need to replace this or that, but in general everything usually costs more than you think and takes twice as long!  Here is my 1303 when I first got her:   I knew I wanted to put a lot of power into this guy, so I started with building up a platform for it. If I can't turn and stop, then I probably shouldn't go really really really fast... really.  Also, I figured starting with these components had a lower learning curve then engine building, so I started by replacing the suspension and steering components thanks to the help of topline parts. With intentions of taking it to autocross events and track days, I want it fun but elegant. Also, I figured starting with these components had a lower learning curve then engine building, so I started by replacing the suspension and steering components thanks to the help of topline parts. With intentions of taking it to autocross events and track days, I want it fun but elegant. Replacing the suspension and steering was not too difficult, and a simple set of tools can get you far. Here are the results of my work! I think it looks pretty sweet.  I have more pictures somewhere of the steering rack and other bushings and assorted steering stuff I replaced... I'll have to find them. After all that was finished, the next step was to order the wheels. I was torn between Cal and Germanlook at the time, and I ordered a set of Centerline wheels in a Chevy bolt pattern and had my rotors accordingly drilled. Tracking down a machinist and many problems from Centerline caused 2-3 months to idle by with no wheels. Here are my Centerline wheels: 15x8 in back and 15x7 up front, these guys have a nice stepped lip. They remind me a bit of phone dials, but are also very different. Anyway, with 225's in back, the meaty tire looks deliciously fast. Not to mention that the wheels weigh about 14lbs a piece, they should be pretty nice on the track.   Ok, well I'm much further ahead, but I will update soon... posting pictures is not as much fun as sawing out your floors! I'll leave you with this though.  I hope you like what I've started, and am looking forward to the help you guys will give me. Can't wait to fit the 2366 and the 901!!! Last edited by Bugged; November 21st 2010 at 03:42. |

|

#2

|

|||

|

|||

Oh man... I put this in the wrong spot... can i get a moderator over here... Oh man... I put this in the wrong spot... can i get a moderator over here...

|

|

#3

|

|||

|

|||

Hi, your project looks very nice. Will the 8 inch tires fit within the rear fenders? Creative Car Craft sell three inch fiber glass fenders, that would set your rear centerline off real nice On my project, which I just can't seem to do anything with. I am using 10 cookies cutters with the three inch fiber glass fenders. It also give it a cool look. Those tires will throw debree on your fender and do damage to your paint job.

|

|

#4

|

|||

|

|||

|

Yeah, I will get wider fenders for the back... probably the creative car craft ones. In the front I may get some fender work done. Just to stretch em out a lil bit. I have some odd offsets going on the wheels, and have added considerable track in the rear and the front. I know there are adverse effects of doing this but no turning back now. It should be really stable accelerating. But I see plenty of bugs with a lot of track added, especially the ones sporting the flared kafer cup fenders.

|

|

#5

|

|||

|

|||

|

Ok! Time for a short procrastination break from my programming homework and a small update. I have both pans cut out of the car and the new right pan is ready to go in, and the left is not far behind. I went to Harbor Freight and picked up their $15 air hammer with assorted chisels, for the removal of the spot welds on the frame. It worked like a charm! I found it easiest to start mid way, like on the rear corner, get under the flap and hammer it upwards. This way, you have a clear shot at the spot welds, whereas sometimes if just trying to run along the lip, you end up shearing off the metal and have to grind it off. Sharpening the chisel also helps tremendously when slipping into those tight, tricky spots. Hopefully I can get these pans welded in this weekend.

Anyone have any cleaning suggestions? I spent some time cleaning off the torsion tubes/frame horn area with some concoction my roommate mixed up... I can't wheel the frame out to pressure wash it because my body is in the way and an engineless Camaro behind that. Also, I need to take my transmission out soon so I can start fitting the 901. I'm a bit worried about getting this bad boy in, but I'll ask about that when I can get some reference pictures up. Where do you guys get your 12 point bits to remove the cv's? Last edited by Bugged; November 21st 2010 at 03:42. |

|

#6

|

||||

|

||||

|

I've had good luck with Oil Eater from Costco, but it's not always available so call ahead if you want to get some. I spray, wait, spray, scrub, spray, scrub, then rinse and see what I have. Depends a lot weather the gunk is buildup of dirt/oil or you have a rusty surface.

Jason

__________________

If I could just get paid for my sleepless nights.... 1960 VW Bug UBRDUB Walkaround 1st Drag Run Dyno Run Oval Ragster-'57 Rag/'04 Boxster S |

|

#7

|

|||

|

|||

|

Drilled 1/4 inch holes spaced about every inch in the pans today. Didn't think I was going to start welding, but I got anxious. Everything started off pretty well, until I heard the welds popping off as they cooled... The frame ledge is twice as thick as the pan itself, so when I thought the pan was welding in, I was basically just filling in the holes and taking my chances with it making a deep weld. I ended up just putting a bunch of stitch welds also, which worked much more easily... I think on the left side of the pan, I'm going to skip the drilling and just stitch weld the thing in... Might just try to do the entire side.

|

|

#8

|

||||

|

||||

|

Nice looking project. You should be able to find the "triple square" bit to remove the CV bolts at any VW parts house or in a small set at an auto parts house. Lots of info on fitting the 901 can be found here if you do a search.

__________________

NO_H2O 72 1302 Smack Black GL 73 Bus (2L CIS Powered) 66 Beetle, 73 Standard Beetle 72 Pinzgauer 710M Volksport Kafer Gruppe |

|

#9

|

|||

|

|||

|

Hey, another question here for the future. when mating the transmission mounts and the 911 trans, can I grind out a groove in the transmission mounts so the bolt bumps on the bell housing have clearance? Or do I have to grind down the bumps themselves... Sorry if the description is vague.

Basically can you grind on a transmission mount? How about a urethane one? |

|

#10

|

||||

|

||||

|

Bugged,

Cheap plug, but here is one approach.. http://www.germanlook.net/forums/sho...6894#post76894 The thread does have some good info to help you plan your approach.. VR Alex

__________________

Alex Olaverri Sales Associate for Bug@5-Speed (US) Email: Bugat5speed@yahoo.com Tele: 973 204-5463 |

|

#11

|

|||

|

|||

|

Alex,

I have been through that thread several times now. I actually already have your rear mount, although according to that thread it appears I have the 914 style mount whilst I have a 71 901/911 transmission. Last edited by Bugged; November 2nd 2010 at 02:09. |

|

#12

|

|||

|

|||

|

Slide 40 Bug@5-Speed Rear Gearbox Support (Cont)

The last order of business is to attach everything to the bell housing with the manufactured supplied bolts/nuts or grade-8 or better hardware[/QUOTE] here it looks like you may have grinded down the trans mounts...?  Or is this before you grinded down the bellhousing? |

|

#13

|

||||

|

||||

|

You really need to move this to the build thread up top!

Jason

__________________

If I could just get paid for my sleepless nights.... 1960 VW Bug UBRDUB Walkaround 1st Drag Run Dyno Run Oval Ragster-'57 Rag/'04 Boxster S |

|

#14

|

||||

|

||||

|

Go into the Project Builds section and start a new thread called Bugged Build and then cut and paste the pictures you've started here onto there. Unless somehow you are locked out?

Jason

__________________

If I could just get paid for my sleepless nights.... 1960 VW Bug UBRDUB Walkaround 1st Drag Run Dyno Run Oval Ragster-'57 Rag/'04 Boxster S |

|

#15

|

|||

|

|||

|

Awesome! Thanks Jason!

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|