|

|

|

|

#1

|

||||

|

||||

|

Hi Wally

Looks good, I didn't get a chance to get back to you with the dimensions, then the forum was down, look like you have it sorted. I even thought about using the stock G50 fork and making it a push rather than a pull clutch. Steve

__________________

STI powered 1303 in the works. |

|

#2

|

||||

|

||||

|

Quote:

Lee and Rich had another great idea as they told me that the front output shafts of the 4 wheel drive 964 (G64 tranny) fitted the G50 and were 100mm (944/T2 size)! So. if that works out, my problem of the axles looks almost solved :-)) |

|

#3

|

||||

|

||||

|

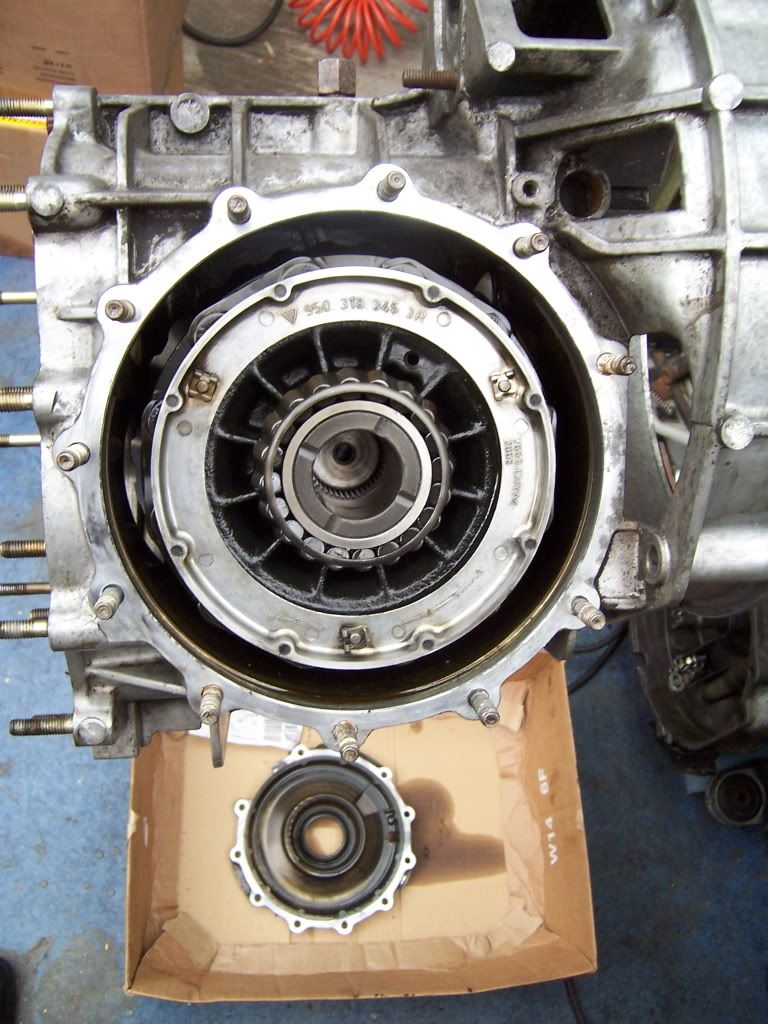

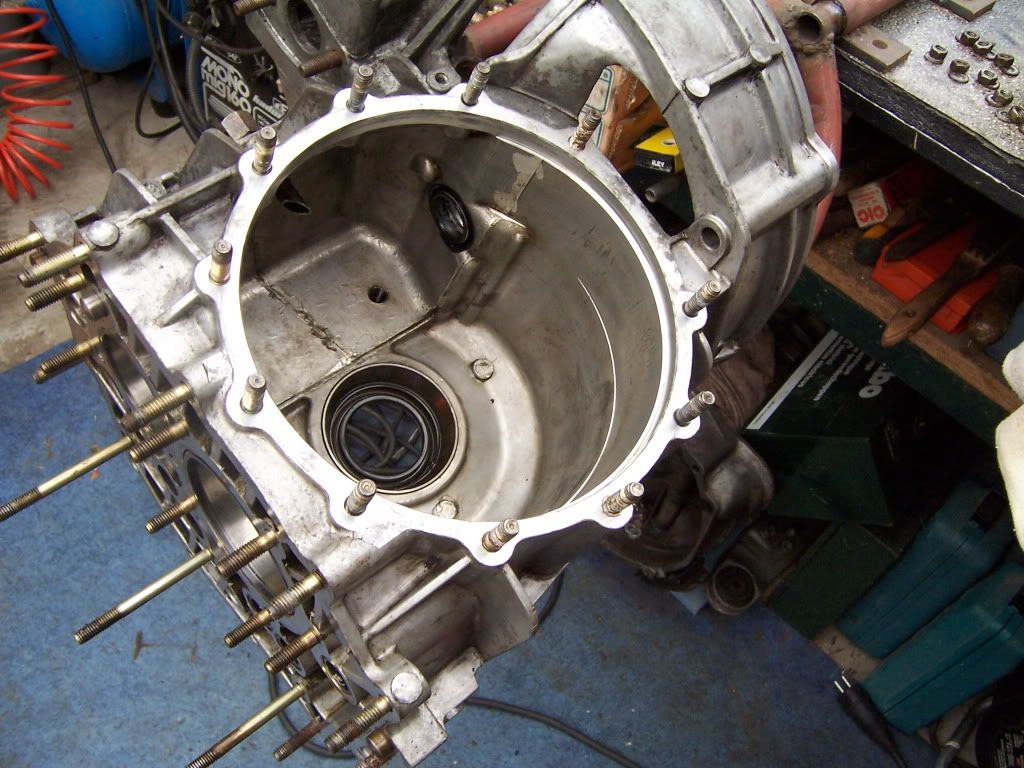

Ok, further removal of all parts in order to be able to machine the housing and main shaft:

Taking the diff out:    Made an adapter plate to mount the Saab bearing onto. The TO bearing itself isn't shortenend yet:

|

|

#4

|

||||

|

||||

|

Not sure anyone is still looking at all these weird complicated parts, but this is the clutch plate I'll be using:

|

|

#5

|

|||

|

|||

|

Quote:

That last pic with the disk, that's a Kennedy from the box in the background? Always thought you had to go solid center at a big power level... guess not! Keep it coming! Can't wait to see how the annular throwout works for you. Here i am struggling with making a 'slave saver' to keep a regular piston slave from binding... You ever have binding problems on your current 915 slave setup? |

|

#6

|

||||

|

||||

|

Thanks for the feedback Clatter, Rich

Quote:

Well, I recently read a leaflet from Sachs where they explained the differences in clutch plate style. Was very informative and sort of opend my eyes as I never really understood what was what with all the availabkle clutches in the type 1 world. Fact is that a solid center can indeed hold more torque. A 4 or 6-puck 'metallic' plate style can hold more torque than an organic disk. But...my own perception is that the diameter of the clutch has a large part in this as well. The type 1 guys always only work with 200mm, so you never hear about them using the diameter of the disk in the equesion. With that limited 200mm diameter, the organic disks have their limits for sure. Thats usually when 'they' step up to x-puck (semi)metallic disks and experience the on/off engagement of the metallic disks... My own experience was that I could launch my 2200 lbs fat chick with me in it on full M&H drag slicks with 345Nm (255 ft lbs) on a stock 225mm (=organic) spring centered disk and stock 915 (old too) PP. Once I had the right leverage figured out on my tranny's clutch arm, I had a very acceptable pedal force and excellent progressive clutch grip. So since I had not found any limits yet on the organic disk of that (similar) size, i hope with the special KEP plate and the HD Sachs PP that I can stretch the limits somewhat further and still enjoy the easy engagement of the organic disk. After all, its a street car that drives on its own wheels to circuits and drag strips. If the organic disk will not hold what I am making now, there is also a 6-puck spring centered disk from KEP in the same dimensions and same G50 center  Even nicer wrt engagement and capable of transmitting huge torque is a two-disk set-up (with organic disks), but that involves a lot, so not yet neccesary Quote:

As I wrote before, the right leverage of the arm is critical, so I would adjust that if at all possible to gain the right amount of throw of the TO bearing, which will prevent binding too. My SACO set with the CNC (its a mark) slave had enough trow in the end I found out. I needed to adjust and adapt quite some untill it was working as well as it finally did last year. Correctly bleeding the set-up is important too...  There are some old posts by Shad Laws where he writes about his Saco set and his 923 (basically a 915) tranny set-up. Maybe that helps some too. |

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

| Thread Tools | |

| Display Modes | |

|

|