|

|

#31

|

||||

|

||||

|

saludos desde Paraguay!!

One notices that you have donates to good work, doing these of zero!!!

__________________

vw standar 1973 vw 1303 sunroof - Automatic Stick Shift 1974 vw variant squareback 1968 VW PARAGUAY |

|

#32

|

||||

|

||||

|

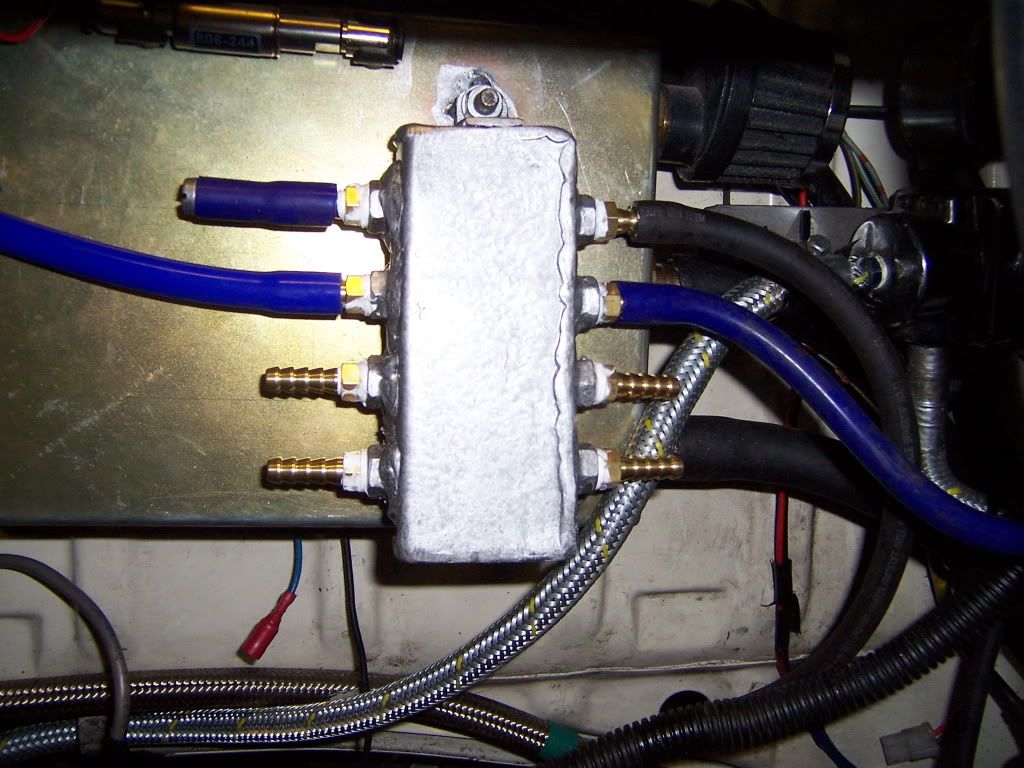

Made a vacuum/boost box for all the pressure lines to connect to instead of all the 'T'- connections in the lines I had up untll now.

I hope it gives a better boost signal this way, which is important for the MAP sensor, fuel pressure regulator and also for the BOV.  In the meantime, I have a 6-puck spring centered on the way from KEP (dual disk is a bit too much $$ for me at this moment) and the flywheel and pressure plate have been machined flat again. To get the diafragma fingers 'straight' (general consensus being that that is when the most torque can be transmitted), we had to machine the outer edge of the flywheel (where the pressure plate resides onto) some 1.5mm deeper than stock. The ratio of machining depth to fingers moving is approx. 1,5 to 1. So, 1.0 mm machining gave about 1.5mm finger movement with this pressure plate. Never thought it needed to be that much. I hope it works out as I have anticipated. The 6-puck is equally thick as the organic one KEP said (8.0mm), so I hope it gets here on time so I can use it next saturday on our first local drag race meet of this year. |

|

#33

|

||||

|

||||

|

Hi Wally

Looking good. A few people I know ran boost boxes and things didn't work as well as would be expected, the extra volume slowed reaction to everything connected to it. Where do you take your signal for your wastegate from? Been told by serious turbo tuners to take it after the throttle plate, that way it reacts to actual motor pressure not the pressure in the between the turbo & throttle plate.

__________________

STI powered 1303 in the works. |

|

#34

|

||||

|

||||

|

Quote:

Quote:

I would be happy to redirect, but its the first time I learn of this. Thanks Steve, Walter |

|

#35

|

||||

|

||||

|

Wally, ever try a solid center clutch disk?

Pete

__________________

'72 super '65 bus '52 split |

|

#36

|

||||

|

||||

|

Nope, not even ever any semi-metallic pad...

|

|

#37

|

||||

|

||||

|

While waiting for the disk to arrive, I cut some polycarbonate ('lexan') sheets for the side windows.

I thought they were lighter than the 1,5kg I saved per side window (2,45 to 0,95kg), but its weight up high, so it will benefit more in the corners I suppose.

|

|

#38

|

||||

|

||||

|

As the 6-puck has not arrived yet and I need to run on sunday, I have reinstalled the old organic disk. Flywheel has been resurfaced and machined down so the pressure plate now has some more pre-load. Fingers are now perfectly horizontal. This should give some better holding power by itself and it did

Boost has again been tuned to 14.5 psi and oh boy what a rush once 3000 rpm gets passed   From the datalog I could see that at about 2850 rpm there is 0.5 bar or 7 psi boost and at 3500 rpm the full 14.5 psi is reached. The engine easily runs up towards 7000 rpm, but I want to stay before that for a little bit longer as I am not sure where max hp will be. Coming saturday there is a local mobile rolling road dyno (more or less just across the street for me) so I will try to enter the car there. I only ran the full boost in 2nd and 3rd as to not risk a premature clutch burn-out but that went well. So fingers crossed for saturday when the dyno run will be done in 4th. Very curieus what it will get, providing the clutch holds  . .

|

|

#39

|

||||

|

||||

|

PLEASE TAKE VIDEO....

Chris.

__________________

74 Std. GL 08 Vw rabbit 18 WR250R 07 Chevy 3500 Dually |

|

#40

|

||||

|

||||

|

I'm going to guess ~340ish HP at the F/W, ~290ish HP at the wheels

My 6 puk solid centre with Kennedy STG2 PP is rated to hold 341 ftlbs of torque. I'm not sure if Wally's clutch is up to the task though ....  Good Luck !! Sandeep |

|

#41

|

||||

|

||||

|

Quote:

Remember that I have a small-ish turbo (same size you had before with the VF39) that on the best of the best tuned subaru's STi's gets 300 rwhp at 20-22 psi. So, 290 -ish hp at the wheels would really be the max for this turbo at its optimum boost level of that 20 psi... Still, its always nice to talk numbers  There are some more dyno-days planned and depending on how it goes, I will try to do a 20 psi run somewhere. On 14th June, there is the Budel meet where I have to defend my last years win of highest aircooled power on the mobile dyno. I only had the stock 2 liter in back then and the wastegate operating on its own internal spring (7 psi), so the 'win' only took 167 hp then  The then next dyno-day is 30th of june (or 1 juli) at Steve's open house in Belgium, where there may be some OFF (outlaw flat four) members when they come to europe for a week of EBI3 and Hessisch-Oldendorf or whatever this meet of really old cars is called  Maybe a magazine will be there too to do a story on some street cars with different hp levels. Their current 4-car line-up only went to 200 hp, so I volunteered Maybe a magazine will be there too to do a story on some street cars with different hp levels. Their current 4-car line-up only went to 200 hp, so I volunteered  Not sure if our schedules match, so we'll see. Not sure if our schedules match, so we'll see.I love dyno events even more than drag racing to be honest. Oh, almost forgot, I bought a slightly (according to the PO) used Bosch Motorsport '044' EFI pump from ebay, which should keep the fuel-flow and -pressure on the safe side. It obviously works well. Also interseting is that the 660 cc Siemens injectors are now back to 1.35 ms opening time at idle. Never could get below 2 ms with Bosch injectors before... PPS: I looked up the VF34 turbo: most say its a 35 lbs/min turbo. I don't know what that means, but it has its flow limits around 300 hp 'they' say

Last edited by Wally; May 21st 2009 at 17:04. |

|

#42

|

||||

|

||||

|

We definitely MUST see a video from the dyno session!!!!

|

|

#43

|

||||

|

||||

|

Good luck with the dyno, and +1 for video

You should be happy with the bosch 044 motorsport pump. I've got one in my car running 50psi and 750cc RC injectors. I also had one with my old setup and it ran flawlessly for 6 years. I prefer the 044 to a walbro any day because they're quieter and more reliable. |

|

#44

|

||||

|

||||

|

Allright, allright, I'll ask a friend to hold the video button pressed for the run

Quote:

Thanks for the confirmation! |

|

#45

|

||||

|

||||

|

My roommate has a walbro pump in his rally car mounted in the trunk next to the fuel cell and when it's running it's as loud as the engine at idle, it really is that bad. I have mine mounted up front with rubber isolators and you can barely hear it when the motor is off, it's surprisingly quiet.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|